Optimizing Industrial Equipment with Temperature and Stress Reducers

Intro: Temperature level and pressure reducers from trusted suppliers make certain steady industrial processes by avoiding changes that trigger downtime and tools damages.

In the middle of a busy plant, a designer meticulously readjusts a control board, monitoring an unexpected change in temperature level and stress. This important minute highlights the essential duty that temperature level and stress reducers play in keeping system stability. A reputable temperature level valve vendor makes sure components are fit to respond to these demands flawlessly. When sourced from ball valve relied on valve factory, these elements integrate efficiently, delivering dependable efficiency. The schedule of wholesale temperature shutoff alternatives simplifies the procedure for sectors going for scalable solutions without compromising high quality, all sustained by responsive wholesale shutoff networks and experienced control valve suppliers.

Advantages of integrating pressure reducers in valve systems

In industrial setups, the integration of stress reducers within valve systems addresses essential efficiency and security challenges. Pressure variations can cause system disruptions, equipment damages, and operational downtime. By integrating stress reducers, an industrial system can maintain consistent stress levels, improving tools durability and process consistency. A trustworthy valve manufacturing facility typically provides components designed with robust materials and exact engineering that accommodate diverse operational demands. Industrial customers commonly prefer a wholesale valve approach to systematize maintenance and substitutes throughout their facilities. Control valve providers working together with temperature shutoff providers further ensure these stress reducers complement temperature level control devices seamlessly, producing a unified system that secures sensitive devices while maximizing source intake and reducing energy waste. This all natural technique contributes to smoother process and better control over complex processes.

Exactly how temperature control valves enhance process security

Temperature level control valves are essential in maintaining the delicate equilibrium in between heat input and output in several commercial situations. Their precise policy of fluid temperatures considerably lowers the risks of getting too hot or freezing, which can jeopardize item high quality and safety. Working together with pressure reducers usually supplied by the exact same control shutoff distributor, temperature level shutoffs make sure systems react adaptively to changing problems. Sourcing these shutoffs from a reputable wholesale temperature valve service provider can likewise reduce purchase intricacies and boost stock management. In numerous valve manufacturing facilities, layouts integrate innovative products and smart control systems that respond swiftly to temperature level shifts, making sure consistent procedure security in time. This integrity not just cultivates better functional self-confidence but also plays an essential role in maintaining smooth workflows by reducing the threat of unforeseen procedure disruptions. By ensuring consistent and accurate control of temperature level and stress, well-coordinated guideline services provide a structure for smoother procedures, highlighting their significance in achieving performance and stability across numerous systems and applications.

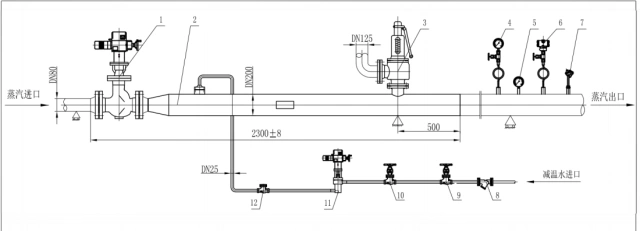

Design considerations for mixed temperature and stress reducer solutions

Creating a system that properly attends to both temperature and pressure control demands a thorough understanding of functional atmospheres and part compatibilities. When collaborating with a temperature valve provider, it is vital to review the material buildings, response times, and integration capacities of their products. Integrating these with pressure reducers sourced by means of a wholesale shutoff network allows customized options that satisfy certain industrial obstacles. Shutoff factories understood for accuracy production concentrate on creating parts that withstand rust, endure high tension, and deal smooth control features without compromising longevity. Additionally, cooperation between control valve suppliers and temperature valve suppliers enhances system consistency, making certain specific modulation of crucial criteria. Thoughtful factors to consider, such as system pressure ratings, temperature ranges, and upkeep demands, eventually result in reliable and adaptable settings up that sustain long term functional success.

Practical industrial systems count on parts from relied on temperature level valve providers and trustworthy wholesale temperature level valve sources, adding to process solidity and devices security. Including options from a seasoned valve manufacturing facility together with wholesale shutoff options not only sustains scalability yet additionally maintains quality criteria vital to safety and productivity. As sectors evolve, collaborations with control valve vendors offering integrated temperature level and pressure reducers offer paths to refined system control. The combination of reputable style, comfort in operation, and adaptive performance creates enduring value that instills confidence in continuous industrial management.

globe valve . Regulating Shutoff-- Controls fluid circulation, pressure, and temperature level in industrial processes.

2. Security Shutoff-- Immediately releases excess pressure to protect tools.

3. Stress and Temperature Instrumentation Ideal Practices-- Discusses finest techniques for pressure and temperature instrumentation in commercial settings.

4. Technological Technologies in Stress Lowering Regulatory authorities-- Explores advancements in pressure reducing regulatory authority innovation.